For many companies, beyond the speed that laser welding guarantees, it is also important to meet quality requirements that traditional methods like TIG or MIG/MAG often cannot guarantee. Increasingly, these standards determine whether your company will win a contract or pass an audit. Check what distinguishes laser welding, what the weld looks like, how it is evaluated, and how its certification proceeds. This knowledge will allow you to safely implement laser technology in production and avoid rejected batches.

Welding vs. Weld - a difference worth remembering

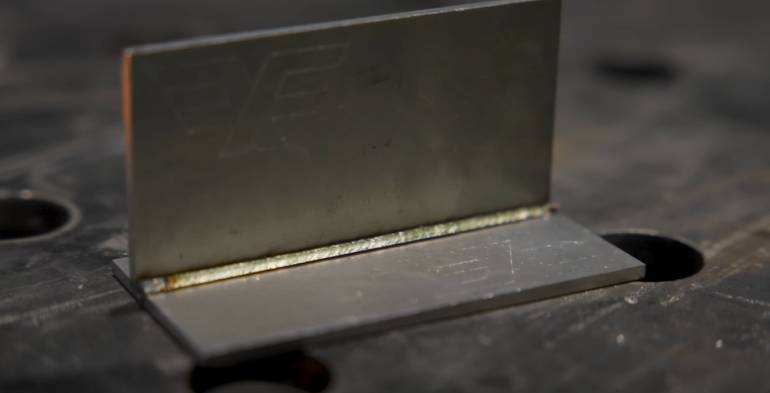

Welding is the process of joining metals. A weld is the result of this process, i.e., the molten and solidified material that forms the joint. When analyzing laser welding, it's not enough to talk about technology; you need to evaluate the weld: its shape, penetration depth, microstructure, and mechanical parameters. It is the weld that determines whether the joint will meet quality standards.

Why does this distinction matter?

Because it's not the process description that goes into quality documentation and under the inspector's scrutiny, but the weld itself. If it doesn't meet standards, an entire production batch can be rejected, regardless of how advanced the welding technology used was.

Want to learn more about how to choose the right laser welder for your needs? Read: Comprehensive guide to laser welders, where you'll find detailed information about available models and their applications.

How does a laser weld compare to TIG, MIG/MAG?

-

An experienced TIG welder can achieve an even, wide weld with an aesthetic, scaly surface, but this process requires enormous precision and is very slow.

-

MIG/MAG allows faster welding, but the weld is wider, with more spatter and usually requires finishing treatment.

-

Laser, thanks to its high precision, creates a narrow and deep weld, allowing for joining even complex forms ideal for materials such as stainless steel or demanding aluminum alloys. It is smooth, almost free of spatter and usually doesn't need grinding with a separate device or straightening of the surrounding material.

The key difference is the small heat-affected zone (HAZ). In laser welding, it is minimal, which translates to less distortion and preservation of the base material's mechanical properties. For thin sheets, this means the possibility of achieving a weld without risk of warping or burn-through.

Laser welding - how does the process differ from TIG, MIG/MAG?

Unlike electric arc, here the laser source is energy introduced pointwise, in the form of a focused light beam. There's no arc, no electrode – there's a beam that can be controlled with accuracy to tenths of a millimeter.

What does this mean in practice?

-

the process is contactless, eliminating many human errors present in manual methods,

-

it requires much better joint preparation: minimal gaps and precise material cleaning, edges must be perfectly clean, without paint and oxides,

-

in most cases, the weld is made autogenously (without filler material), although welding wire can optionally be used, unlike in MIG/MAG where it is the basic filling material,

-

parameters (power, speed, spot diameter, shielding gas) are digitally controlled, allowing real-time correction and ensuring process repeatability; thanks to this, after loading a program, almost anyone can independently start welding and consistently achieve good results.

Interested in practical application of laser welding? Check: Handheld laser welder Fanuci 5.0 PRO GenX – an ideal solution for precision welding work that minimizes the need for final treatment.

Quality control and certification of laser welds

Laser welding stands out not only in appearance but also in the rigor of control. Every weld must pass tests according to standards, and the process must undergo formal qualification.

Quality testing

-

visual (VT) – evaluation of face profile, continuity, absence of undercuts and cracks,

-

penetrant (PT) – detection of surface microcracks, especially in high-alloy materials,

-

radiographic (RT) – internal control, detection of pores and lack of penetration,

-

ultrasonic (UT) – used for thicker welds.

Mechanical tests

As part of technology qualification and production acceptance, tests are performed:

-

bending,

-

tensile,

-

impact,

-

hardness testing (HV) in the weld and heat-affected zone.

Weld quality classes in the welding process

Standards PN-EN ISO 13919-1 (for steel) and 13919-2 (for aluminum) define three levels, where high quality is precisely determined by classes:

-

B – highest quality, minimal tolerances for defects (e.g., aviation, nuclear energy),

-

C – standard level for industrial constructions,

-

D – allows greater non-conformities in less loaded constructions.

Laser as a process often allows achieving class B, provided that preparation and parameters are properly selected.

Want to learn how to achieve the highest precision in laser welding? See how precision laser welding using Fanuci equipment can revolutionize your production.

Documents and standards

For the process to be recognized, the following are essential:

-

WPS (Welding Procedure Specification) – workstation instruction defining welding parameters,

-

WPQR (Welding Procedure Qualification Record) – document confirming technology qualification based on sample testing.

Basic standards in this area are:

-

EN ISO 15614-11 – laser welding technology qualification,

-

EN ISO 13919-1/2 – weld quality classes,

-

EN ISO 9606-1/2 – welder and operator qualification.

Without valid WPQR and WPS documents, laser welds will not be accepted, for example, by UDT inspectors or classification societies.

Summary

Precision laser welding allows creating narrow, smooth welds, and the cleanliness of the process and repeatability make it a technology revolutionizing standards in the welding industry. Laser technology enables achieving the highest weld quality classes, i.e., levels expected even in the most demanding industries. If you're considering implementing laser welding in your company and want to understand what standards, procedures, and tests will apply to your production, schedule a free consultation with an expert.