Modern production requires technology that ensures high quality, savings and efficiency. In the era of rising costs of materials, energy and labor, more and more companies are deciding to optimize welding processes. Fanuci laser welders are one of the most innovative solutions, allowing for precise welds at significantly lower operating costs. Precise laser welding in fiber optic technology is not only higher quality and speed of the process, but also real savings on the consumption of consumables and energy. What are the main advantages of this technology and why should you invest in Fanuci equipment for welding processes?

What makes Fanuci welders stand out? Why should you choose them?

Fanuci welders are a combination of modern technology, reliability and savings. Thanks to the use of fiber laser, the devices ensure the highest quality of welds and durable connections, increased efficiency and the possibility of automating production processes. The laser welding process using a fiber laser is characterized by exceptional precision, as it allows for accurate targeting of the light beam at the welding area. Concentrated energy melts the edges of the connected elements, and after they solidify, a durable and aesthetic weld is formed.

Companies deciding to invest in this technology can count on significant reduction of operating costs and increased competitiveness in the market. Learn about the key features that distinguish Fanuci welders.

Check out our Laser Welders Guide

Increased speed and production flexibility

Laser welding using fiber optic technology is many times faster than traditional methods such as TIG or MIG/MAG. Thanks to this, processing time is significantly shortened, and production processes become more efficient. Fanuci welders enable work at speeds of up to 10 meters per minute, which allows companies to significantly accelerate project implementation and increase production line throughput.

Unmatched precision and weld quality

Laser welding allows for high-quality welds while minimizing material waste. This technology eliminates element deformations, and smooth and clean connections often do not require additional processing. This is crucial in industries where precision and aesthetics matter.

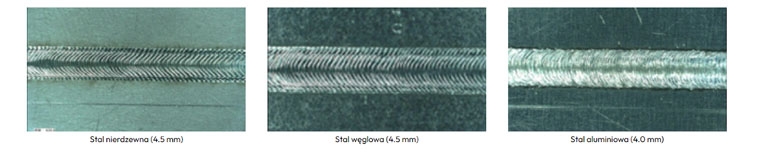

Versatility and ability to join different materials

Fanuci welders allow for joining a wide range of materials, including stainless steel, aluminum and precious metals. The ability to weld elements of different thicknesses and join different materials opens new design and production possibilities, increasing flexibility in the implementation of complex constructions.

Full weld penetration without deformation

One of the greatest advantages of laser welding technology is deep weld penetration without the risk of deformation. Welds are characterized by high strength in applications requiring durable and precise connections without weakening the material structure.

Non-contact and single-sided welding process

Laser welding does not require direct contact with the material. This translates to less equipment wear and extends its lifespan. Additionally, the possibility of single-sided welding makes this technology particularly useful for elements with complex geometry, where access to the weld is limited.

Ease of automation and low qualification requirements

Fanuci welders are optimized for full automation and integration with industrial robots. Thanks to this, they can be part of advanced production lines. Additionally, their operation is intuitive and does not require specialized welding qualifications, which significantly reduces operator training costs.

Low operating costs and minimal maintenance

Fiber laser technology allows for reducing operating costs through lower energy consumption. Annual savings can reach tens of thousands of zloty, which results not only from reduced energy consumption, but also lower demand for welding and consumable materials. Expensive post-processing procedures are in many cases eliminated or significantly shortened, which additionally optimizes the production budget. Moreover, the lifespan of the fiber source is estimated at 100,000 hours, which means that the welder can work continuously for many years, minimizing the need for servicing and component replacement.

FANUCI welders consume 30-40% less shielding gas compared to traditional methods (TIG or MIG/MAG), and also 10-15% less welding wire. Thanks to this, operating costs decrease. This makes the investment in laser welders pay back multiple times over the long term. Additionally, FANUCI welders can be powered by external photovoltaic modules up to 3 kW power, which further reduces operating costs.

Welding modes adapted to different applications

Users of Fanuci welders can switch between pulsed and continuous mode, thanks to which they can adapt the entire process to specific applications. This is particularly important in the case of different types of materials and constructions requiring precise adjustment of welding parameters.

Where do Fanuci welders find application?

Laser welding is a technology that works well in various branches of industry, providing durable and precise connections. Fanuci welders are widely used: they work well in metalwork and balustrade production, as they allow for quick joining of metal elements of any shape without the need for additional processing. In the gastronomy industry, they are used to produce dishes and accessories made of stainless steel, ensuring durability and hygienic finish. Steel constructions, loft furniture and the automotive industry are other sectors where Fanuci welders guarantee durable and repeatable welds and high quality workmanship.

Fiber technology also finds application in aviation, where every gram of mass counts, and welds must meet the highest safety standards. Thanks to appropriate parameter regulation, Fanuci welders also work well when joining plastics in the electronics industry and medical industry.

FANUCI laser welders find application everywhere where precision, quality and efficiency count in the welding process, allowing companies to optimize costs and increase competitiveness.

How to choose the right Fanuci equipment?

Choosing the right laser welder should be adapted to the specifics of work – the type of processed materials, required precision and scale of production. It is worth paying attention to several key aspects that affect the efficiency and convenience of using the device:

-

laser power – crucial for weld penetration and efficiency. Too high power can cause excessive heating of the material and its deformation, while too low may not provide adequate penetration depth, resulting in weak element connection.

-

material type – not all welders are optimal for every alloy. The type of alloy is crucial for choosing the right equipment, as different metals have different heat conduction properties, laser beam reflection and susceptibility to deformation.

-

mobility and automation – some models enable integration with industrial robots, and thanks to Industry 4.0 support, remote control and monitoring are possible, which facilitates production optimization and better resource utilization. Among laser welder models, there are also those that offer compact construction, enabling easy movement within the facility.

-

operating costs – effective management of energy and consumable materials consumption translates into real savings in the welding process.

Read: Welding cost reduction – how to effectively reduce metal joining costs in industry?

Welder power and certification

Welder power is crucial for the types of materials that can be processed. FANUCI PRO GenX is a model offering the highest power, which allows welding thick and demanding elements. While models FANUCI PRO Portable and FANUCI Compact have lower power, so they work better with thinner materials.

Choosing machines without proper certifications can involve risks such as losing contracts or problems with equipment approval for use. FANUCI welders meet all required standards, having CE, SGS, TUV and FDA certificates, which ensures their reliability, compliance with regulations and complete operational safety.

Operating mode and mobility

If the equipment is to be used in multi-shift mode, it is worth choosing a model adapted to intensive operation. All Fanuci welders – FANUCI PRO GenX, Portable and Compact – allow multi-shift operation. This means they are adapted to intensive operation: they can work without breaks for extended periods. This is particularly important in production companies, where downtime generates losses, and process continuity affects efficiency and order fulfillment timeliness.

Welder mobility (portability) is another important aspect. The FANUCI PRO Portable model stands out with its compact size, lightweight construction and ease of transport. This is an ideal solution for companies that need a welder for field applications or require flexibility in organizing workspace.

Control system and Industry 4.0

Advanced control enables precise setting of welding parameters. FANUCI PRO GenX is the only model equipped with wireless control and Industry 4.0 function, which allows for remote monitoring and integration with other systems. This is particularly important in large production facilities, where quick parameter adjustment without having to approach the machine saves time. Additionally, the company can improve welding process management, minimize downtime and better control operating costs.

Cooling system

The cooling system affects welder performance and work stability. FANUCI PRO GenX and Compact use liquid cooling, which provides better heat dissipation and allows for longer operation without device overheating. FANUCI Portable instead has an air cooling system – it does not require additional cooling systems, making this device model more compact and simpler to operate.

Why is Fanuci the best investment for your company?

Rising production costs, lack of qualified welders and the need to increase efficiency – these are challenges that every modern company faces. FANUCI laser welders are the answer to these needs, providing higher precision, lower operating costs and ease of operation, which allows for effective staff utilization. Thanks to the use of modern FANUCI technologies, material losses are minimized, labor costs are reduced and the need for time-consuming post-processing is eliminated. This is a solution for companies that want to increase their competitiveness and adapt to Industry 4.0 standards.

By choosing FANUCI, you gain not only the highest class equipment, but also comprehensive technical support, professional training and the possibility of future modernization. Investment in modern technologies has never been so profitable – shorten production time, increase efficiency and save on operating costs.