Cheap laser welders tempt with low prices, however when investing in such equipment, many entrepreneurs succumb to the temptation of choosing the cheapest option without considering the long-term consequences. This apparent saving quickly becomes a costly mistake. A day of downtime can cost tens of thousands of zloty – this is just the tip of the iceberg of hidden expenses. Companies with cheaper welders regularly struggle with long waiting times for service, faster-wearing components and frequent downtime. Therefore, top-class welders, despite the higher initial price, actually reduce the total cost of ownership (TCO) over 3-5 years. In this article, we expose key traps of low-cost solutions and show why quality is actually the most profitable business decision.

5 traps when choosing a budget laser welder

Trap #1: Lack of adequate service support

When a laser welder suddenly stops working, every hour counts. Unfortunately, many owners of low-cost devices learn this painfully, waiting for service for weeks.

What does "cheap service" really mean in practice?

Budget welder suppliers often lack a local technical team. In practice, this means:

-

waiting for a technician to arrive from abroad,

-

communication through a translator or only by email,

-

need to import spare parts.

The situation becomes particularly problematic in case of laser source failure. Many customers of low-cost devices report that after just a few months of use, the laser source breaks down, which must be sent to China independently, and the waiting time for repair or replacement reaches even several months. During this time, the machine stands idle, generating huge losses. If additionally the device is no longer covered by warranty, the cost of a new source can reach an amount comparable to the price of the entire budget machine.

Hidden costs of delayed service

The real cost of downtime is not only the inability to fulfill current orders. It is also:

-

wages of idle employees,

-

contractual penalties for missing deadlines,

-

loss of customers discouraged by delays,

-

opportunity costs – outsourcing work to subcontractors, thus higher prices.

How to recognize a laser welder manufacturer with real service support?

Before purchasing a welder, ask the potential supplier specific questions:

-

How many service technicians work in Poland and where are they located?

-

What is the guaranteed service response time from notification?

-

Does the company have its own spare parts warehouse in the country?

-

Does it offer remote technical support and diagnostics?

A key question is also the availability of replacement sources during repair time. Professional suppliers, aware of the critical importance of production continuity, offer bridge solutions - replacement sources that can be installed during the repair of a damaged component, thus eliminating costly downtime

Practical tip: Ask the supplier for contact with two current customers who used the service within the last 6 months. Their experiences will tell you more than advertising brochures.

Before making a purchase decision, it is worth knowing all the technical and economic aspects of solutions available on the market. Check our guide to laser welders, which will help you better understand key parameters and functions affecting the efficiency of these devices.

Trap #2: Higher failure rate and lower component durability

The difference between a budget and premium welder becomes most apparent after 12-18 months of use. That's when problems begin that turn initial savings into growing cost bills.

It is worth emphasizing that premium welders are associated with quality known among European manufacturers, which is uncommon for most laser welders that are manufactured from A to Z in China. For example, Fanuci Pro series machines are assembled in the USA using the highest quality components, and their laser sources use advanced technology, ensuring reliability. Interestingly, Fanuci welders, despite partial production in China, represent such a high class of devices that they are not sold on the Asian market at all, where budget solutions dominate.

How long do laser sources really last?

The laser source is the heart of the welder - a key and most expensive component of the device:

-

High-quality fiber laser sources (e.g., in Fanuci welders): 100,000 hours of operation - that's over 11 years of continuous use in 3-shift production.

-

Budget sources: usually 10,000-30,000 hours, which with intensive use means replacement after just 3-4 years.

What is even more disturbing, in typically Chinese welders, repaired sources are often installed in new machines. In practice, this means that their actual lifespan can drastically drop even after a few months of use. There are also cases where from the very beginning some pumps stop working properly, resulting in the user never achieving the declared device power, and consequently - expected production efficiency.

Cost of source replacement? Even 40-60% of the value of the entire welder. This one difference can negate all initial savings.

Critical components and their actual durability

Apart from the laser source, the biggest differences concern:

-

Cooling system - in budget models, cheaper pumps are used, which:

-

fail 2-3 times more often,

-

require replacement every 3000-5000 hours instead of 10,000+ in premium,

-

replacement cost: 4000-7000 PLN.

-

-

Beam guiding optics - cheaper glasses and anti-reflective coatings:

-

overheat faster,

-

lose parameters,

-

each replacement costs several thousand PLN plus downtime.

-

-

Control electronics - lower class capacitors and integrated circuits:

-

greater sensitivity to voltage fluctuations,

-

on average 30% shorter failure-free operation time,

-

failure often requires replacement of entire modules instead of individual components.

-

How does component quality affect the welding process?

Inferior components mean not only more frequent failures, but also:

-

unstable laser beam parameters that directly affect welding quality,

-

gradual degradation of weld quality without visible failure,

-

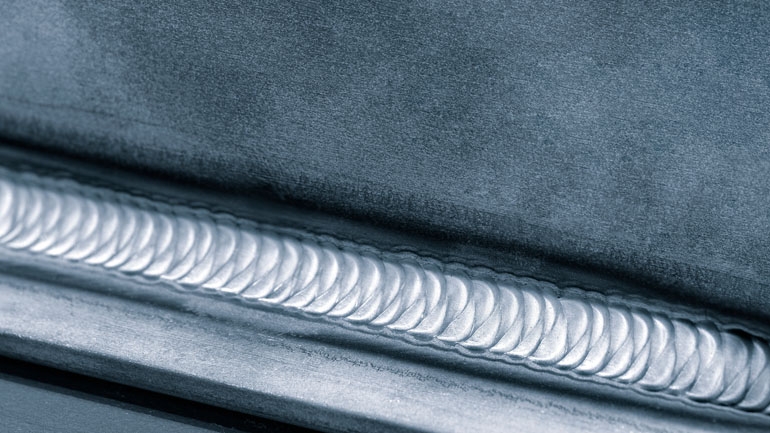

power fluctuations resulting in uneven welds and the need for corrections,

-

greater susceptibility to overheating during intensive work.

Thanks to advanced technical parameters, premium welders offer welding capabilities for a wide range of materials, including difficult-to-weld special alloys.

Practical tip: When comparing offers, divide the device price by the declared lifespan of main components. You will get the real cost per hour of operation - often premium welders turn out to be cheaper per hour of operation.

Trap #3: Lower technical parameters and performance

On paper, two welders may have identical specifications, but in practice work completely differently. This difference often costs more than the initial savings on purchase.

Declared vs. actual power – what do budget welders hide?

Manufacturers of low-cost devices often provide peak parameters instead of continuous ones:

-

a welder advertised as "3 kW" may maintain this power only for short pulses,

-

in continuous operation it actually achieves 2-2.5 kW.

Laser beam quality – a key parameter you won't find in specifications

The lower the BPP value, the better the energy concentration. In practice, this means:

-

better weld precision (difference even 0.1-0.2 mm),

-

deeper penetration (up to 30% difference with the same settings),

-

lower risk of thermal deformation of the material.

Practical limitations in welding different materials

Cheaper laser welders often encounter difficulties with:

-

highly reflective materials (aluminum, copper, brass), stainless steel,

-

connections of different metals (e.g., steel + aluminum),

-

long work cycles.

Despite these limitations, laser welding technology finds application in an increasingly wide spectrum of industries, wherever precision, aesthetics and repeatability are crucial, and companies aware of its long-term benefits invest in high-quality solutions. Laser welding is increasingly entering the automotive industry, where both strength and aesthetics of connections are required.

How does lower performance translate to real costs?

-

40-60% higher labor costs.

-

Longer order fulfillment time.

-

Lower production throughput.

-

Higher consumption of energy and consumables.

Key questions to ask before purchasing a laser welder

Key questions before purchase are not only price, but also laser power, which determines the device's capabilities in terms of types and thicknesses of welded materials

-

What is the actual continuous power (not peak) of the device?

-

What laser beam quality (BPP) can I expect?

-

What materials and in what thicknesses can I weld?

-

How long can the device work continuously at full power?

Practical tip: Before finalizing the purchase, ask for a test welding of exactly the same elements you will be producing. Measure the process time, verify weld quality and penetration depth. This simple test will reveal the real difference in performance better than catalog data.

Trap #4: Lack of development and modernization possibilities

Manufacturing companies develop dynamically, and welding technologies evolve. Low-cost laser welders quickly become a closed development path, forcing complete equipment replacement with every change in needs.

Why do cheaper welders quickly become obsolete?

Budget devices usually:

-

are based on closed system architecture,

-

use proprietary software without update possibilities,

-

do not have interfaces for integration with external systems,

-

have limited hardware expansion possibilities.

Specific technical limitations in budget welders

-

Closed control systems:

-

no possibility of software updates,

-

inability to add new functions or welding modes,

-

limited parameter configuration possibilities.

-

-

Lack of Industry 4.0 interfaces:

-

absence of standard communication protocols (OPC UA, MQTT),

-

lack of connectors for industrial network connection,

-

inability for remote monitoring and control.

-

-

Hardware limitations:

-

maximum supported laser source power (without replacement possibility),

-

fixed welding head configuration,

-

no possibility to add additional movement axes or manipulators.

-

When buying a laser welder, you're not just buying a device for today - you're investing in your company's future. Choosing a technologically closed welder may seem like savings, but in reality it's a road to nowhere, forcing continuous, costly replacements of entire equipment with every change in production requirements.

Trap #5: Hidden operating costs

Daily operating costs of a laser welder quickly exceed its purchase price. This is exactly where budget devices generate the biggest, though often not immediately visible, losses.

Energy consumption – differences visible on bills

Premium and budget laser welders differ in energy efficiency:

-

low-cost welders: energy efficiency 20-25%,

-

premium welders (e.g., Fanuci): efficiency 30-35%.

With average consumption of 10 kWh daily, the difference is 2-3 kWh daily, or about 500-750 kWh monthly. At a price of 0.80 PLN/kWh, this gives 400-600 PLN monthly, or 4800-7200 PLN annually in additional energy costs for the cheaper device.

Consumption of technical gases and consumables

Precise process control in premium welders translates to measurable savings:

-

shielding gas: Fanuci welders consume 30-40% less gas than budget devices,

-

welding wire: 10-15% consumption reduction.

Analysis of actual welding costs shows that savings resulting from choosing premium equipment quickly compensate for the higher initial investment, especially with high production load.

How does inaccurate welding generate hidden material costs?

Lower precision of budget welders leads to:

-

More rejects.

-

Wider welds.

-

Larger heat affected zone.

Additional processing – hidden thief of time and money

Budget welders often require additional post-welding operations:

-

grinding and polishing welds,

-

straightening deformed elements,

-

cleaning spatter.

How to measure actual operating costs of a laser welder?

Before purchasing a welder, conduct a comparative test on a representative production sample:

-

Measure precisely:

-

welding time,

-

amount of gas and wire consumed,

-

number of rejects,

-

time needed for finishing operations.

-

-

Convert results to monthly production scale.

-

Compare total operating costs, not just technical parameters.

A high-class laser welder like Fanuci starts generating savings from the first day of use, among other things thanks to its precision. With typical production load, the difference in operating costs between a premium and budget welder can amount to 30,000-45,000 PLN annually – an amount that often exceeds the purchase price difference already in the first year of use.

Total cost of ownership (TCO) – the key to rational investment decisions

Making a decision to buy a laser welder based solely on the initial price is like choosing a car based only on purchase cost – it ignores all other expenses that will appear during operation.

What exactly is TCO and why is it the most important indicator?

Total Cost of Ownership (TCO) is the sum of all expenses related to the device throughout its entire period of use:

TCO = Purchase price + Operating costs throughout the entire period of use

This indicator allows you to see the real cost of a welder, going beyond the price tag. In the case of laser welders, the difference between initial price and TCO can be astonishing – cheaper devices often generate 2-3 times higher total costs over 5 years.

Analysis of laser welder prices is just the beginning of profitability analysis – it's crucial to include all TCO components, which will reveal the real economic advantage of premium solutions.

Practical tips for independent TCO estimation when purchasing a laser welder

-

Collect operating cost data – ask the supplier for energy, gas and consumables consumption specifications for typical tasks.

-

Estimate downtime cost – multiply the number of potential downtime hours by the hourly work cost (including employee wages, facility fixed costs and lost revenue).

-

Check service schedule – ask the supplier about recommended inspections and typical replacement parts along with prices.

-

Include financing cost – if you plan leasing or credit, add interest to TCO.

Fanuci welders - quality that pays off

After analyzing the traps of low-cost welders, it's time to look at specific premium solutions. Fanuci welders stand out with parameters that directly translate to efficiency and savings in daily production. They are widely used in various industries, ensuring both aesthetics and durability of connections.

What distinguishes Fanuci welders from other solutions?

Instead of general quality assurances, let's look at specific technical parameters and their practical benefits:

-

High welding precision – Fanuci welders guarantee excellent precision welding at 0.1 mm level allows joining even the thinnest elements (from 0.5 mm) without deformation.

-

Fiber laser source lifespan – 100,000 hours of operation without parameter loss (over 11 years of three-shift work).

-

Real operational savings:

-

30-40% lower shielding gas consumption compared to TIG/MIG/MAG,

-

10-15% reduction in welding wire consumption,

-

elimination of post-processing needs (grinding, polishing).

-

-

Full Industry 4.0 compatibility

-

Professional technical support, which in the case of working with handheld laser welders is crucial for maintaining production continuity:

-

service technicians in Poland,

-

local spare parts warehouse in Gdansk,

-

service response within 24 hours.

-

Fanuci welders ensure exceptional precision while maintaining parameter stability even during long-term work.

Practical tips when choosing a Fanuci welder model:

-

Conduct an audit of the current welding process:

-

measure actual welding time (without preparation and processing),

-

calculate consumables consumption,

-

determine the number of elements requiring corrections.

-

-

Define priority parameters:

-

mobility vs. performance,

-

degree of automation,

-

range of materials to weld.

-

-

Test the device on your own parts:

-

bring your materials to the presentation,

-

measure welding time compared to current method,

-

check weld quality without additional processing.

-

Welder operation comes down to selecting the appropriate operating mode and adjusting basic parameters through an intuitive touch panel, ensuring ease of use even for inexperienced operators Unlike TIG/MIG/MAG methods, it doesn't require years of experience or specialized manual skills.

Summary

Choosing a low-cost laser welder can lead to significantly higher long-term expenses than the initial savings on purchase. Five most common traps of low-cost devices: inefficient service support, shorter component lifespan, limited technical parameters, lack of modernization possibilities, and high operating costs.

Total cost of ownership (TCO) reveals that seemingly cheaper solutions generate significantly higher expenses over several years, while premium devices, despite higher initial price, provide substantial savings through better energy efficiency, lower material consumption and rare downtime. When choosing a laser welder, attention should be paid to all aspects of ownership costs, not just the initial price – it's crucial to consider service quality, component durability, actual technical parameters and development possibilities. Investing in quality is not a cost, but a long-term, economically justified business decision.