Fiber laser cutting technology is becoming the standard in modern industrial production, replacing less efficient and more expensive methods. Precise cutting, minimization of material waste, and the ability to automate processes make fiber lasers widely used in various production sectors. Companies are increasingly investing in laser cutting machines to improve machining quality, increase productivity, and optimize operational costs. What equipment should you choose to meet these requirements?

Laser processing of sheet metal - precision and efficiency of fiber technology

Modern laser cutting machines allow achieving excellent edge quality and eliminate the need for additional processing. Laser cutting of sheets and other materials is exceptionally precise thanks to the focused light beam, which reduces thermal distortions and ensures repeatability of results. Compared to traditional methods such as plasma or water cutting, fiber laser technology offers greater process control, lower consumption of operating materials, and the ability to work with a wide range of metal alloys and composite materials. The laser cutting process allows for the realization of both large constructions and extremely precise details with microscopic dimensions.

Laser technologies used in sheet metal processing - CO₂ or fiber?

The choice between CO₂ laser and fiber laser is crucial for optimizing sheet metal cutting production processes. Each technology has its advantages, however modern facilities increasingly choose fiber laser due to its efficiency and economy.

CO₂ lasers were the industry standard for years, but their technology is gradually giving way to modern solutions. These devices generate a laser beam using CO₂ gas and require expensive optics to focus it. Their advantage is the ability to cut very thick sheets, but this process involves higher energy consumption and greater operating costs. The need for regular maintenance and optics replacement makes CO₂ laser operation more expensive and less efficient in the long term.

Fiber technology is currently the most advanced solution in sheet metal processing. These lasers use active optical fibers to generate and guide the beam, eliminating the need for complex optics. Their main advantages are:

-

high precision - narrow focus point and high energy density allow achieving excellent cutting quality, minimizing distortions,

-

increased efficiency - ability to cut both thin and thick materials at higher speed compared to traditional methods,

-

lower operating costs - no need for complex maintenance and lower consumption of operating materials reduce operational costs,

-

energy efficiency - fiber lasers consume significantly less energy than CO₂ lasers, which translates to lower bills,

-

lower cutting gas consumption - optimization of cutting parameters allows for reduced gas utilization.

What to pay attention to when choosing a laser cutting machine for sheet metal?

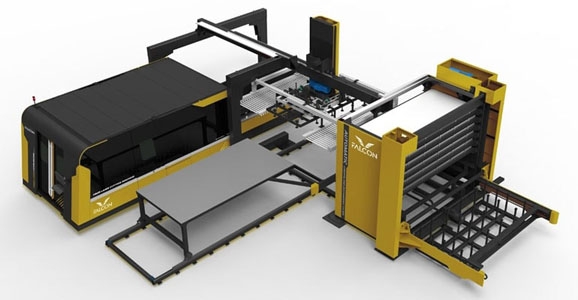

The decision to purchase a laser cutting machine is a strategic investment that can significantly impact the efficiency and competitiveness of an enterprise. Choosing the right model should be tailored to production specifics, types of processed materials, and requirements for precision and efficiency. Modern devices, such as Falcon S Masterline, have been designed with maximizing work efficiency and minimizing operating costs in mind. It is therefore worth paying attention to key functions and parameters that distinguish Falcon S Masterline devices from competitive solutions:

-

laser power - minimum power required to cut through a given material thickness guarantees processing effectiveness, while higher power allows increasing cutting speed and improving edge quality. In case of large production series, higher power can translate to shorter work cycles and thus greater efficiency of the entire facility. Falcon S Masterline devices are available in various power variants: from 2000W to 24000W.

-

precision and automation - not all devices available on the market offer such advanced solutions. Falcon S Masterline uses an advanced automatic beam focus adjustment system (Auto Focus). This technology allows for dynamic parameter adjustment in real time, eliminating errors resulting from variable material thickness or irregular surface.

Additionally, an active collision avoidance system minimizes the risk of cutting head damage, which increases safety and process reliability, while the 3D cutting head enables cutting at angles up to 45 degrees. The combination of these solutions ensures stable and efficient processing in both individual and series production.

-

operating costs - compared to traditional cutting methods, cutting machines using fiber technology significantly reduce the consumption of cutting gases and operating materials, which directly translates to lower operational costs. Efficient energy utilization and component longevity (fiber source lifespan is approximately 100,000 hours) make the investment in a laser cutting machine quickly pay off with intensive use.

-

process automation through additional options - modern Falcon S Masterline cutting machines can be equipped with sheet metal storage systems or automatic exchange tables. Integration with Industry 4.0 control systems enables optimization of the entire production process.

Thanks to these functionalities, Falcon S Masterline is a choice that allows companies not only to increase precision and processing efficiency, but also minimize operating costs and optimize the entire production process. It's an investment that enhances competitiveness and opens new development opportunities in a dynamically changing market.

What sheet metals can be laser processed?

Fiber lasers allow for precise processing of various metals, including stainless steel, carbon steel, aluminum, copper, and brass. Depending on the chemical composition and material structure, it is necessary to adjust cutting parameters such as laser power, gas pressure, and processing speed.

Some materials require special device configuration, which may be more demanding in terms of processing precision. It is also worth considering the maximum thickness of cut sheets - for most industrial applications, the optimal range is up to 20 mm.

Investment in modern sheet metal processing technologies

Not all devices available on the market offer such advanced technologies as our equipment. Some companies still rely on outdated systems that limit their potential, generating higher operating costs and longer downtime. Meanwhile, investment in modern cutting machines is a way to optimize every stage of production - from the first cut to the final detail finishing. Precise cutting, material savings, and minimized downtime translate to faster return on investment and competitive advantage. Falcon S Masterline stands out with precise automation, maximum efficiency, and reliability, allowing your company to operate faster and cheaper.

In a world where time, precision, and cost optimization matter, Falcon S Masterline cutting machines give you the advantage. Choose technology that works for you - contact us and select a solution tailored to your needs.