A fiber laser cutting machine is an investment that can fundamentally change the efficiency of your production. Where many cutting methods fail – due to limited precision, high operating costs, or tool wear – fiber laser enters with full force: faster, more accurate, and cheaper. Thanks to the contactless laser cutting process, minimal heat influence, and the ability to cut even the most complex shapes, fiber laser has become the standard in production. In this article, we'll show why this technology is displacing other solutions and how it can help your company produce faster, more economically, and with better final results.

Revolution in sheet metal processing - what is laser cutting?

If today you outsource sheet metal cutting and hear "it can't be done" or "it will need to be ground afterward," it means you haven't yet dealt with laser cutting technology, which has changed industry standards. Laser cutting technology – especially in the fiber version – allows cutting even very complex shapes with accuracy to tenths of a millimeter.

Unlike plasma or mechanical processing, there's no friction here, no wearing tools, and no need to correct edges. The laser beam doesn't just cut through the material, but does it cleanly, quickly, and predictably – without risk of deformation.

For production, this is a concrete difference in the laser cutting process: less waste, faster process, no finishing processing. No wonder fiber laser is displacing other solutions – especially where precision, repeatability, and real savings in material consumption matter.

If you want to learn detailed principles of this technology, check our comprehensive guide about what laser cutting is and what materials can be processed with it.

Key advantages that justify investment in a laser cutting machine

Unmatched precision and edge quality

In other processing methods, such as plasma cutting, operators often have to account for spatter, the need to grind edges, and time loss on finishing processing during laser cutting. Laser eliminates these stages. Modern laser cutting machines – especially those working in fiber technology – allow cutting shapes with accuracy reaching 0.1 mm, even with thin materials.

This means not only repeatability of details, but also real process shortening – if the edge is smooth and doesn't require manual correction, the detail can immediately proceed to the next production stage or assembly. Example? In facilities making decorative elements from stainless steel, the laser cutting process allows skipping grinding and polishing – saving labor hours and avoiding human errors.

What's important – precise laser cutting minimizes thermal deformations. In practice: if you're cutting elements with delicate geometry or narrow bridges between details, laser will handle what plasma would leave as warped sheet metal. This is not only quality improvement, but elimination of entire batches of rejects.

Significant acceleration of production processes

In the laser cutting process, speed doesn't mean quality compromises. On the contrary – fiber laser achieves speeds unattainable for other technologies, especially with thin sheets. For comparison: where plasma handles a sheet in several minutes, laser performs the same shape several times faster – and without the need for manual finishing.

In practice, this means the operator simultaneously supervises several cutting cycles in the time previously needed for one. In companies working on just-in-time orders, the ability to deliver a finished detail "today" instead of "tomorrow" can be decisive. Laser cutting speed translates directly into production efficiency.

Waste minimization and optimal material utilization

Modern nesting software – such as in control systems of Falcon laser cutting machines – automatically arranges elements to maximally utilize the sheet surface. Even a few percent improvement in layout means thousands of zloty in monthly savings in serial production.

Laser also reduces cutting gas consumption during the laser cutting process. Instead of constantly supplying large amounts as with plasma cutting, fiber systems need much less – and for thicker materials, you can even switch to cutting with compressed air. Less gas, fewer downtime periods, lower component consumption.

All this means that real material loss after implementing laser cutting technology can drop by even 30-40%. And this means that the investment not only works faster and more accurately – but also does it cheaper.

Ease of operation and required training

For many companies, the barrier to purchasing advanced laser cutting machines is not the device price itself, but the concern: will we be able to operate it? In the case of modern laser cutting machines, such as Falcon, this concern disappears on the first day of working with the machine.

Automation that simplifies everything

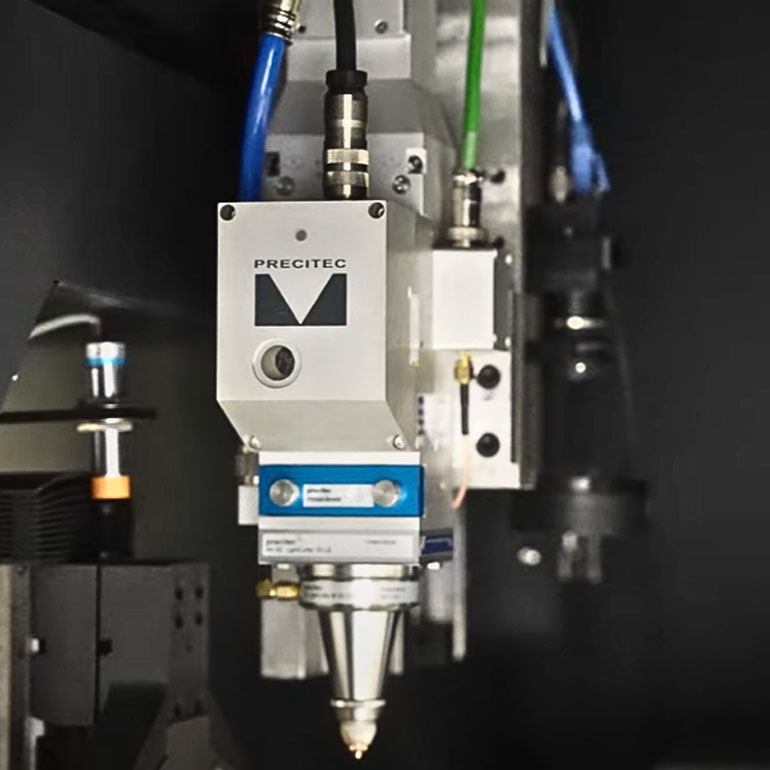

Today's laser cutting machines no longer require an operator-engineer who spends hours setting dozens of parameters. In Falcon cutters, it's enough to indicate the type and thickness of material – the system automatically selects laser power, cutting speed, gas pressure, piercing, focal length.

The Auto-Focus system automatically sets the laser beam focus point during laser cutting. Even when changing sheet thickness or profiles of different thickness, the head reacts automatically and adjusts settings in real time. If you use sheets of different thicknesses – you don't need to readjust anything.

The operator has a touch interface at disposal, from which they manage the entire process. Thanks to the ability to work on a tablet, they don't even need to approach the machine to change settings.

Three days of training – and ready

Complete training of a laser cutter operator takes three days. That's enough for a new employee without experience in laser technology to independently prepare a project, start cutting, and handle basic service situations.

Lower recruitment costs and faster implementation

For a company owner, ease of operation means something much more important than "work comfort":

-

no need to search for hard-to-find, experienced operators,

-

no need to spend months implementing people into the process,

-

no need to hire a second person "for shifts, in case of error."

Modern laser cutting machines allow working with a smaller team because they reduce the risk of errors and the need for manual corrections. The cutting process is predictable – regardless of shift, operator, and material.

It's not just cutting – it's a way to improve entire production

A machine that automatically selects settings eliminates one of the most common causes of errors and waste: incorrectly selected parameters. If today you have to spend time on corrections, recalculations, and fixes – after implementing a system like Falcon, they disappear from daily work.

In practice, this means:

-

fewer errors and complaints,

-

greater production repeatability,

-

faster new project implementation (even same day),

-

greater flexibility in shift planning.

Modern laser cutting technologies and automation in cutting machines

In older cutting machines, everything depended on the operator during the laser cutting process. You had to manually set parameters, select appropriate gas pressure, set focal length, cutting speed, laser power – and hope that the person wouldn't make a mistake in any of dozens of settings. Today it looks completely different – modern laser cutting machines know how to cut by themselves.

It's enough to select material and its thickness, and the system automatically selects cutting parameters – optimal for the given case. Software like CYPCUT analyzes data and sets laser power, feed rate, gas pressure, and even cutting sequence within the laser cutting range. Thanks to this, incorrect burns or damaged edges simply stop happening.

The cutter also optimizes element placement on the sheet (so-called nesting), allowing maximum material utilization – without the need for manual detail arrangement during material processing. Additionally, the system can determine the sequence in the laser cutting process to limit heat influence and prevent deformations on thin sheets.

What else makes the operator's work easier:

-

Auto-piercing – the device automatically selects energy needed to "penetrate" the material.

-

Gas regulation – the system ensures gas pressure is always adapted to the given cutting phase.

-

Collision avoidance – sensors analyze sheet surface and modify cutting path if they detect warping.

For the facility owner, this is not only convenience, but concrete benefits: fewer errors, less waste, fewer corrections, faster production preparation time, and no downtime. Even if the operator has little experience, the system will guide them. And if you have a larger team – you no longer need to make production quality dependent on one "machine person."

Moreover, modern cutters can monitor component condition – e.g., optics – and inform about service necessity before failure occurs. You no longer need to stick to rigid maintenance schedules or wait until something stops working. This eliminates downtime and allows planning work in advance.

A modern laser cutter doesn't just cut. It selects settings, monitors quality, suggests how to use the sheet to the last centimeter. In practice – it gives the operator ready solutions, and the company: repeatability, predictability, and peace of mind.

Financial perspective: investment that pays off

The decision to purchase a laser cutter is not an expense – it's thoughtful capital allocation. Production company owners don't invest for technology's sake. They invest to reduce fixed costs, increase process predictability, and improve financial results. And that's exactly what fiber technology provides.

Purchase cost is just the beginning – TCO matters

A good-quality laser cutter costs from several hundred thousand to several million zloty. On paper, it may seem more expensive than plasma or CO₂ laser. But the purchase cost alone says little if you don't consider what happens next: energy, consumables, production errors, operator labor hours, and downtime.

In practice, TCO (Total Cost of Ownership) of modern fiber laser cutters can be lower than with cheaper devices. After 3-5 years of intensive work, the difference in operating costs can reach dozens of percent.

Faster cutting = faster return

With fiber laser, you handle thin sheet several times faster than plasma, significantly increasing production efficiency. What does this mean in practice? If today you need two shifts to complete weekly production, after laser implementation you might find you can do it in one. These are real savings in labor costs – not just in a table.

Additionally: detail edges during fiber laser sheet cutting don't require further grinding. You save time and give up additional stages that normally consume labor hours.

Such effects are not exceptional. Read how one company, thanks to a laser cutter, shortened production time by 30-40% and reduced labor costs by over 330,000 zloty.

Less waste, better material utilization

Cutting precision, narrow kerf, and automatic nesting allow squeezing much more from a sheet of metal.

Same quality – regardless of operator

Thanks to parameter automation and intuitive software, even a less experienced employee can start production with minimal error risk. You no longer need to base production continuity on two "best operators" because the system monitors setting correctness. This means less risk of downtime and fewer complaints due to human errors.

Energy efficiency that translates to bills

A 4 kW fiber laser consumes about 18 kW of energy, while its CO₂ counterpart needs more than three times as much. If the device works several hours daily throughout the year, the difference in electricity bills can be five-digit.

Better service, less stress

The fiber laser source has a declared lifespan of up to 100,000 hours. This means that for many years the device can work without needing to replace the most expensive components. Additionally, sensors monitor head or optics condition and inform about service necessity in advance – before failure occurs. And if something happens, remote diagnostics capability or 24-hour parts delivery limits downtime to minimum.

How much does it all give?

Let's sum up:

-

lower material consumption,

-

less waste,

-

fewer labor hours,

-

faster production,

-

lower energy consumption,

-

rarer failures,

-

fewer errors.

All this adds up to real, measurable savings. That's why companies that count not only purchase cost but also ownership costs increasingly choose fiber technology. Because it's not about how much you pay at start. It's about how much you gain daily for the next 5-10 years.

Comparison with other metal cutting methods

For someone making an investment decision, technology description alone is not enough. What's needed is an answer to the question: will fiber laser really perform better than what we use today – and is it worth entering it right now?

Below we compare fiber laser with other popular cutting methods – mechanical, plasma, CO₂, oxygen cutting, and water – in the context of what really matters: accuracy, speed, material range, costs, and typical industrial applications.

1. Precision and edge quality

If you produce details that must fit together perfectly or cannot require further processing – fiber laser cutting is the right direction. It enables achieving tolerances of 0.1 mm and gives smooth, clean edges without slag or burns. In most cases, there's no need for additional grinding.

For comparison:

-

Plasma – precision around 0.5 mm, possible slight beveling. It's a cheap machine, good for thick materials, where precision is less important and laser becomes a less cost-effective solution.

-

Waterjet – good precision, but often dependent on abrasive quality and settings. No heat influence, but slower pace. Water cutter leaves a lot of sludge after cutting (mixture of water, abrasive, and material remains). The resulting dirt must be regularly removed, which can be time-consuming.

-

CO₂ – good quality, but less stable with thin, reflective materials.

-

Oxygen and mechanical methods – clearly lower edge quality and greater risk of deformation.

2. Speed and completion pace

Fiber laser is currently the fastest method for cutting thin and medium sheets, allowing wide application in serial production. Speed matters especially in serial production: shorter cycle = more elements completed daily = faster order completion.

How other technologies perform:

-

Plasma: good speed with thicker sheets (>8 mm), but with thin ones it loses to laser.

-

Waterjet: very precise, but definitely slowest. Mainly used where heat cannot be introduced.

-

CO₂: handles medium thicknesses well, but slower than fiber, especially with thin stainless steel or aluminum.

-

Oxygen cutting: definitely slowest, often limiting production pace.

3. Material range and thicknesses

Fiber laser excellently handles cutting a wide range of materials – carbon steel, stainless steel, aluminum, copper, or brass – including reflective materials that CO₂ often can't handle. The optimal range is thin and medium sheets (up to 20 mm), but thick material cutting is also possible (even up to 30-40 mm) with appropriate power.

For comparison:

-

Plasma: ideal for thick steel (above 20 mm), but worse in thinner ranges and less accurate.

-

Waterjet: most universal, cuts almost everything – from metal, through ceramics, to glass. But not suitable for large series.

-

CO₂: limitations in aluminum and copper. Better performance with carbon steels.

-

Oxygen and mechanical: good for simple shapes and thick materials, but limited in precision and range.

4. Operating costs and consumption

This is one of the key areas where fiber wins in the long term. Lower energy consumption, significantly lower cutting gas consumption, long source life (100,000 working hours). Fiber "just works," and for a long time.

Other technologies:

-

Plasma: cheaper at entry, but high operating costs (electrode and nozzle replacement).

-

CO₂: expensive both in purchase and maintenance – requires specialized components and frequent maintenance.

-

Waterjet: consumes a lot of energy and abrasive – operating costs can be surprising.

-

Mechanical methods: cheap to use, but limited in automation and precision.

5. Heat affected zone and distortion

The smaller the temperature influence on material, the smaller the risk of deformation – thus fewer corrections and waste. Fiber laser has minimal heat affected zone (HAZ), so even thin sheets don't deform. This is especially important for elements to be later welded or press-fitted.

Comparison:

-

Plasma and oxygen cutting: large HAZ, risk of warping.

-

Waterjet: no HAZ – ideal for heat-sensitive materials.

-

CO₂: larger HAZ than fiber.

-

Mechanical: no HAZ, but risk of mechanical material deformation.

Warranty, service and reliability - key to production continuity

A cutter can be technologically excellent, but if it stops working at a crucial moment – it's not the equipment that decides your competitiveness, but service availability. Downtime? Even one day can cost tens of thousands of zloty. That's why it's worth asking: what happens when something breaks?

It's not just technology that matters, but who delivers it

Choosing a reliable laser cutter supplier doesn't end with catalog price. What's crucial is whether in case of failure:

-

service responds the same day,

-

needed part is available immediately,

-

if necessary, you get replacement head or source during repair.

If a "bottleneck" appears at any of these stages – production stops. And with it: people without work, deadlines with contractors, contractual penalties, and subcontractors who step in for you. This is not hypothetical risk. This is everyday reality for companies that decided on low-budget machines without real service support.

Choosing the right supplier and model are key investment decisions. What to pay attention to when buying a laser cutter? – check our detailed guide that will help you make an informed decision.

24-hour service, repair often at first visit

In proven systems, like Falcon, service contact occurs immediately after reporting. Many malfunctions can be diagnosed remotely – the service technician connects to the machine online, checks errors, and often removes the problem without visiting. And if a visit is needed? Usually within 24 hours.

What's important: the service technician arrives with specific parts – not to "see what's happening," but to repair. And in most cases does it immediately, because they have all basic elements with them.

Spare heads and laser sources – your security

In case of head or laser source failure, the worst scenario is having to wait weeks for repair in Asia. That's why professional suppliers offer a bridge solution – temporary source or head installation so the machine can still work. Repair takes place locally, in Poland, without need for dismantling and shipping the entire device. This is not luxury. This is real strategy securing production continuity.

Warranty that really works

Market standard is 2-year warranties, but with cutters from PRO segment you can count on 5 years – covering the entire device, not just selected components. It's worth checking if warranty also applies to source and head, because these are the most expensive machine elements.

Parts availability immediately

It's not about whether the part is in warehouse. It's about where it is. In case of Falcon cutters, the spare parts warehouse is in Poland – in Gdansk. It contains both standard consumables and key components such as sources or heads. Thanks to this, time from reporting to full machine functionality is counted in hours, not weeks.

Real impact on TCO

On paper, two machines may look similar. But if one required a total of 4 downtimes of 2 weeks each over 5 years, and the other – none, the difference in costs doesn't close with the "invoice" number. It's a difference in liquidity, reputation, and profits.

That's why service and reliability are one of the key elements affecting Total Cost of Ownership (TCO). Because the most expensive thing about any machine are not components. The most expensive is time when it doesn't work.

Summary: Why investment in laser cutter is a step into the future?

A laser cutter is not another laser cutting machine. It's a device that shortens order completion time, limits material consumption, and eliminates the need for finishing processing. If you have situations in your company today where orders are delayed, waste goes to scrap, and operators spend hours on corrections – laser will not only change this. It will do it faster and more accurately than you think.

If you're looking for a reliable laser cutting machine that combines the latest fiber technology with ease of operation and comprehensive service support, Falcon cutters are the perfect choice. Thanks to advanced automation, minimal training requirements, and local service available 24/7, this investment guarantees smooth production for years. The spare parts warehouse in Gdansk and possibility of free tests on your materials eliminate risks associated with purchase. Contact our advisor to see how Falcon cutter can increase production efficiency and lower costs in your company.