Laser cutting today is not just about precision and speed – it's a real operational advantage. In manufacturing companies, where every hour of work and every millimeter of material counts, laser cutting costs can determine the profitability of the entire order. So how can you optimize this process without compromising quality? In this material, we show how fiber technology and advanced automation – for example with Falcon cutters – allow you to significantly reduce operational costs, shorten lead times and limit losses that often undermine project profitability.

What actually generates costs in laser cutting?

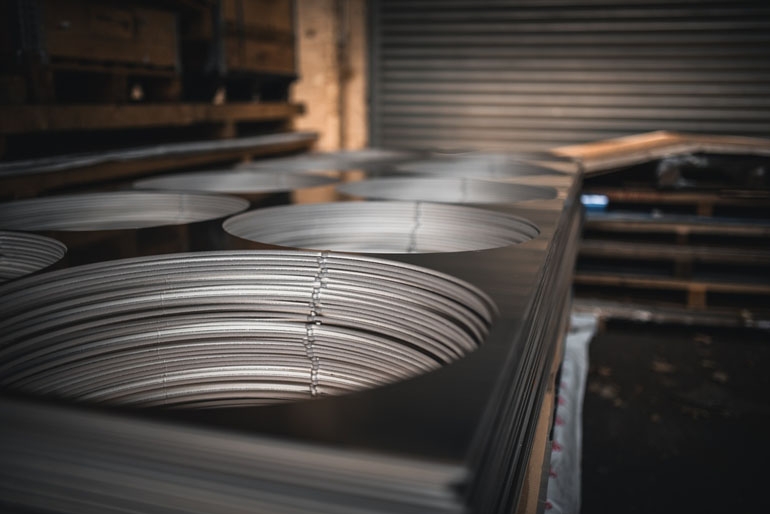

Costs associated with laser cutting result from many elements that may seemingly appear secondary, but on a monthly or yearly scale can generate significant financial burdens. It usually starts with machine preparation issues – in companies that process materials of different thicknesses (e.g., 1 mm, 2 mm, 3 mm), each change involves the need for manual parameter setting. This not only extends lead time but also increases the risk of technological errors.

Another issue is the quality of the cut itself. Burns, crooked edges, surface deformations – each of these defects can mean the need for correction or complete rejection of the element. In practice, this is material waste, but also operator time, who instead of fulfilling the next order, must return to the previous one.

Costs related to energy consumption and technical gases are also significant. Depending on the type of material being processed (e.g., black sheet metal, aluminum, or PVC or acrylic), it's necessary to use appropriate auxiliary gases – often expensive, and their consumption increases significantly with longer cycles and non-optimal settings.

Then there's the human factor. Lack of automation means the need for constant operator presence at the machine, as well as risks associated with errors during manual changeover. In companies that work on multiple projects simultaneously, downtime related to loading new files, setting parameters, and testing are real losses that accumulate every day. Awareness of all cost-generating elements allows accurate identification of areas where real savings are possible – and this directly translates to the price of laser cutting services.

How does fiber technology help reduce costs in laser cutting?

The use of fiber optic laser technology in laser cutting equipment allows significant reduction of operational costs – both in daily operation and in longer-term investment perspective. This is a solution that combines modernity with solid savings.

Precise elimination of losses

Fiber lasers, which are also very popular in the welding process, enable very precise cutting of thin and medium materials, starting from 1 mm thickness. This minimizes the risk of technological errors such as burns, rough edges, or deformations. In practice, this means less waste and reduced need for re-manufacturing parts. Every failed element is, after all, a cost of raw material, energy, and operator work.

Faster and cheaper – case study in practice

Fiber technology actually shortens production time. Example? In the case of a road sign manufacturer, implementing a cutter with unwinder and fiber technology allowed shortening the production cycle by 30–40%. Additionally, it was possible to reduce annual labor costs by over 330,000 PLN.

This is not a theoretical calculation – it's the result of well-selected technology preceded by audit and process analysis.

Lower energy consumption and operation

Thanks to higher light beam efficiency, fiber lasers can be up to 30% more energy-efficient than CO₂, especially with thin sheets. This translates to real monthly savings, especially with multi-shift operation. Moreover, light sources in fiber technology achieve lifespans of up to 100,000 hours – which in turn allows avoiding costly interruptions and frequent component replacement.

Smooth edges, less processing

Cutting under nitrogen protection allows obtaining exceptionally smooth edges. This reduces the need for further grinding, deburring, or additional welding. In many cases, parts can be immediately directed to further assembly or packaging.

Process automation – the key to savings that aren't visible at first glance

High cutting precision is one thing – but it's automation that makes laser cutting really start working for the company's financial results. Falcon models use solutions that eliminate human errors, shorten preparation time, and allow better material management.

Control systems in Falcon laser cutters work in the background, but their impact is visible in numbers:

-

automatic focusing (autofocus) – independent adjustment of the head to material thickness eliminates the need for manual setting,

-

gas pressure regulation – dynamic adjustment to the type of cut material optimizes consumption and improves edge quality,

-

cutting algorithms – the machine automatically selects laser power and speed depending on part geometry, which increases repeatability and shortens operational time,

-

integrated CYPCUT + CYPNEST system – intelligent nesting using material database allows minimizing waste and shortening cutting path.

The result? Significant savings – especially with high order variability or short series, where every minute of changeover and every wasted sheet can cost real money. In practice, such implementation translates not only to lower unit cost of cutting service, but also to greater production flexibility and faster return on investment.

Why does parameter selection have such a huge impact on costs?

In laser cutting, there's no room for randomness. Every parameter – from laser power to cutting path – has a direct impact on material consumption, working time, and final part quality. Therefore, parameter selection is not a matter of convenience, but a key element of cost calculation. See what errors in settings can generate costs – and how our laser cutters eliminate them:

|

Problem with manual setting |

Impact on costs and quality |

How do Falcon cutters solve this problem? |

|

Too high power or wrong cutting speed |

Rough edges, deformations |

Automatic speed and power calibration depending on material thickness |

|

Wrong auxiliary gas selection and pressure |

Increased consumption, higher energy costs |

Real-time pressure regulation – precise adjustment to specific material |

|

Non-optimal path and file nesting |

More waste, worse material utilization |

CYPCUT + CYPNEST system optimizes cutting layout for sheets and profiles |

|

Diverse orders for different materials |

Time-consuming changeovers, increased labor costs |

Changeover automation – Falcon recognizes material and adjusts without intervention |

Thanks to setting automation, Falcon laser cutters eliminate errors resulting from manual data entry. The operator no longer has to manually calibrate the machine for each thickness or material type – the system analyzes, adjusts parameters, and maintains the highest quality without the need for additional intervention. This is not only time savings, but above all cost stability – because every well-selected path, every saved 0.1 bar or few seconds of production cycle, on a monthly scale gives measurable financial effect.

Check: Falcon laser cutters

Falcon equipment – machines for companies that count every detail

If laser cutting is a key stage in your production process, every minute and every percent of material consumption matters for profitability. Falcon are laser cutters that respond to the real needs of modern manufacturing companies – both in sheet processing and cutting tubes and profiles. That's exactly why it's worth considering investment in these devices – designed with companies in mind that focus on quality, efficiency, and scalability.

Here's what you gain by implementing our solutions:

-

best results in cutting thin and medium sheets as well as tubes and profiles – without quality compromises,

-

production flexibility thanks to the ability to work as an autonomous workstation or element of an automated line,

-

full integration with Industry 4.0 – including remote control, automatic reporting, and real-time data analysis.

Looking for a way to actually reduce laser cutting costs in your company? Check the capabilities of the Falcon series on the CNC Machine Center website and schedule an individual presentation.