Is your company struggling with staff shortages, high labor costs, and the need to increase production precision? The solution may be automation, but traditional industrial robots require enormous investments in safety infrastructure and complex programming. Fortunately, there is an alternative – cobots, or collaborative robots, which can work hand in hand with your employees. These intelligent machines are revolutionizing the way small and medium-sized manufacturing companies think about automation, offering flexibility, safety, and quick return on investment. See how cobots can transform your production and why more and more companies are choosing this breakthrough technology.

What are cobots? Definition, construction and basic features

If you are looking for ways to streamline processes and increase efficiency in metal production, you are probably considering automation. In this context, the concept of "cobots" appears more and more frequently. What exactly are these devices and how can they support your company? You will find answers below.

Revolution in production – why cobots?

Cobots, or collaborative robots, are a response to the growing demand of manufacturing companies, especially smaller and medium-sized ones, for flexible and safe automation solutions. They were designed with the idea of working directly hand in hand with humans in the same workspace, eliminating the need to build expensive safety barriers. This concept gained popularity around 2008, mainly thanks to the Danish company Universal Robots, which is a leading manufacturer in this field.

Definition and key differences from industrial robots

A cobot is "a specially designed robot that can jointly perform tasks with humans in direct proximity." This is a fundamental difference compared to traditional industrial robots, which, due to their speed and strength, must be separated from humans, for example with fences or safety curtains, to avoid collision risks.

Key features that distinguish cobots are:

-

Collaboration safety: Cobots have built-in collision detection mechanisms and force and speed limiting. In case of contact with humans, they automatically stop. Their construction minimizes the risk of injury – they are smaller, lighter (usually below 100 kg of own weight) and have rounded edges.

-

Ease of operation and programming: Collaborative robots are often equipped with intuitive graphical interfaces. They also enable so-called teach-by-demonstration programming, which means that the operator can manually move the robot arm to the desired position, and the robot will remember this movement. The ease of programming cobots makes it possible for even people without prior robotics experience to quickly master the basics of their operation. Thanks to this, even employees without advanced technical knowledge can learn the basics of cobot programming.

-

Flexibility and mobility: Cobots are easy to relocate and quick to retool for new tasks. For example, the same cobot can be used one day to operate a CNC lathe, and the next day moved to work with an edge press, changing only the gripper and program. Traditional robots, on the other hand, are often permanently attached to the floor and require complicated modifications when changing applications.

Cobots blur the line between the previously separate worlds of human and machine work, enabling new models of production organization.

Construction and safety mechanisms

Safety is the foundation of cobot construction, enabling their direct cooperation with humans. The main solutions are:

-

Collision detection systems: Based on measuring force and torques in joints. When the cobot senses sudden resistance (e.g., contact with a human or obstacle), movement stops immediately. Standards such as ISO/TS 15066 specify acceptable pressure values that are safe for humans.

-

Speed and power limitation: Cobots move slower than traditional robots (maximum speeds are about 1–2 m/s, compared to 3–4 m/s for industrial robots). They also have lower powers and payloads (most commonly from several to several dozen kilograms), which limits the energy of potential impact.

-

Construction minimizing pinch risk: Cobots are designed without sharp edges and points where fingers could be trapped. All protruding elements are rounded or shielded, and arm profiles are slender. Drives are often positioned in a way that allows slipping or bending in case of collision, instead of rigid pressure. Many cobots have sensitive torque sensors or elastic elements (compliance series) in joints that allow contact detection before crushing occurs.

Safety standards such as ISO 10218-1/2 and ISO/TS 15066 distinguish several modes of human-robot collaboration. Most commonly used for cobots are:

-

Power and Force Limiting mode (PFL): The robot is structurally safe and reacts to contact by stopping.

-

Speed & Separation Monitoring mode (SSM): Uses external sensors (laser scanners, cameras, "sensitive skins" on the robot) to track human position, slowing down or stopping the robot to maintain safe distance. This mode allows for slightly faster work and greater payloads, but requires additional sensors.

However, it is important to remember that although cobots are subject to general regulations such as the Machinery Directive 2006/42/EC, requiring risk analysis and compliance with safety principles, the cobot manufacturer provides a certified arm unit, but complete safety of the workstation depends on the integrator/user. If a dangerous tool (e.g., blade, welding torch, laser) or hard gripper is mounted on the cobot, it can still pose a threat. Therefore, a comprehensive risk assessment for the specific application is always required, which may indicate the need for additional safeguards such as laser radiation shields or welding fume extractors. The cobot provides safe drive and force control, but does not eliminate all process hazards.

Application of cobots in manufacturing companies – with special focus on metal processing

Cobots, thanks to their unique features – flexibility, easy programmability, and the ability to work alongside humans – have found applications in many industries, from automotive and electronics to food industry. Their application in various industrial sectors results from universality and the ability to adapt to production processes. They work particularly well in tasks requiring high precision, repeatability, and interaction with the operator.

Cobots in metal processing: precision, safety and efficiency

The metal processing industry is one of the key areas where cobots play an increasingly important role. They are commonly used for tasks such as:

-

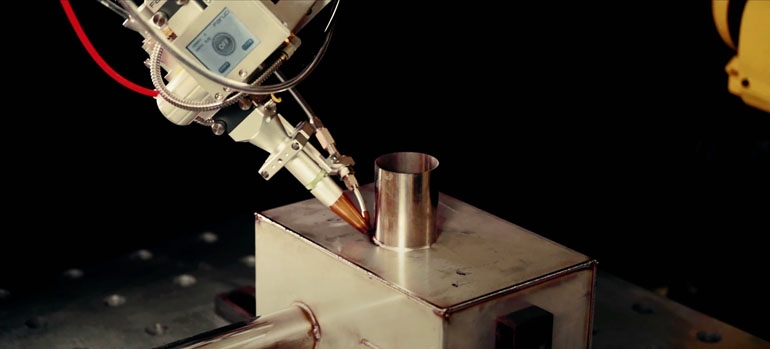

Welding: The precision of cobots allows achieving high-quality welds. They are particularly effective in small and medium-series production, where flexibility and quick retooling matter. The speed of cobot implementation compared to traditional automation solutions is another advantage of this technology. Fanuci & Falcon offers robotic welding-laser station FANUCI 5.0 TurnKey, where a cobot with laser head can weld, cut, clean surfaces and build up metal in one system. Machine operation by cobots also includes mounting mechanical elements with high precision. Such laser systems ensure high precision and safety thanks to complete shields and sensors.

-

Grinding and polishing: Thanks to force sensors, cobots can perform grinding with uniform pressure, replacing the operator in monotonous and physically demanding work.

-

Cutting: The precision of cobot movement makes them effective also in cutting operations.

-

Loading/unloading CNC machines: Cobots can operate CNC machines, feeding and receiving parts, which increases machine utilization and relieves workers from monotonous activities.

-

Feeding/receiving hot elements: In foundries and forges, cobots can feed or receive heated elements from machines, eliminating human exposure to high temperatures.

The ability to safely collaborate with humans in one workspace means that cobots perfectly fit the needs of companies that want to automate selected production stages without the need for costly reconstruction of the entire line. They are particularly valuable where the process is repeatable but requires frequent changeovers or human participation.

Benefits of implementing cobots for your company

Implementing collaborative robots can bring your company a number of measurable benefits, both at the operational and strategic level:

Increased productivity and efficiency

Cobots can work continuously, 24 hours a day, 7 days a week, with unchanging repeatability, which significantly increases production efficiency. Cobot production is developing dynamically worldwide, which translates to better availability and competitiveness of companies using these solutions.

Cost reduction

Cobots simplify the automation process because their installation is often faster and cheaper, does not require building expensive enclosures or complicated safety systems. Thanks to intuitive programming, simple applications can be implemented by companies on their own, minimizing the need for external integrator support. All this makes the barrier to entry into robotization much lower.

Quality and repeatability improvement

In tasks requiring precision, such as welding or assembly, cobots allow achieving repeatable quality that is difficult to maintain by humans in the long term. Elimination of human errors and constant precision of cobot movement contribute to reducing the percentage of defects in production.

Increased worker safety

Cobots are perfectly suited to take over tasks that are monotonous, ergonomically demanding, or dangerous for humans. They can perform tedious operations such as repeatedly inserting and removing parts from a machine, carry objects within established payload limits, or work in harmful conditions, e.g., at high temperatures. This translates to less crew fatigue, reduction of injuries (e.g., spinal disorders) and overall improvement in work safety. The cobot can serve as an assistant, allowing the worker to focus on more complex tasks.

Flexibility and ease of adaptation

Cobots can be easily reprogrammed and used for many tasks in different parts of the facility, unlike traditional robotic stations, often dedicated to one application. Easy programming allows quick adaptation of the robot to different tasks without engaging specialized teams. This enables efficient small-series production on automated stations — if programs and tooling are ready, changing product or process takes only hours, not weeks. For companies with diversified assortment or frequently changing production plans, a universal cobot can serve as an "all-purpose worker."

Solving the labor shortage problem

In the face of staff shortages in the labor market, cobots can significantly increase production capacity and help maintain production pace. They can work continuously, performing tasks for which it is difficult to find suitable workers.

Space optimization

Thanks to the ability to work in close proximity to humans without the need for enclosures, cobots allow better utilization of available space in the production hall. They are smaller and lighter than traditional industrial robots, which also translates to space savings.

Quick return on investment (ROI)

This results from a combination of higher productivity, savings on error/defect costs, and the ability to delegate workers to more valuable tasks. In many cases, investment in a cobot pays off quickly, especially in the face of rising labor costs and labor shortages.

Challenges and important aspects to consider before implementation

Despite many advantages, cobots are not a universal solution for every situation. Their capabilities and potential challenges should be realistically assessed.

Cobot limitations

On one hand, cobots offer many benefits, on the other hand, they have certain limitations that should be considered before implementation.

-

Lower efficiency and payload: To ensure safety, cobots are limited in terms of speed, force, and own weight. This means they do not match traditional industrial robots in tasks requiring very high speed, precision at high dynamics, or carrying heavy loads. Most cobots lift a maximum of several dozen kilograms and move at speeds up to about 1–1.5 m/s. In the case of palletizing very heavy products (e.g., 50 kg bags) or very fast packaging lines, the cobot may prove to be a "bottleneck."

-

Complex or unstable processes: Cobots work best in repeatable tasks with constant conditions. If the process requires dynamic adaptation to major changes or making decisions on the fly (beyond simple program logic), difficulties may arise. Automation of disordered processes (e.g., parts in random orientation) would require advanced vision systems and AI, which significantly increases the cost and complexity of implementation.

Key safety aspects and standards

A common myth is the belief that cobots are inherently safe and do not require additional precautions. In reality, although the cobot minimizes collision risk, this does not exempt from the obligation to conduct a full workplace risk assessment and meet OHS requirements. Errors in configuration or improper use of the cobot can lead to accidents, for example, if speed/force limits are changed in the controller, or if the robot grabs a sharp part and swings it. The cobot manufacturer provides basic safeguards (so-called "safety base"), but the integrator or user must take care of everything else.

Additional hazards related to the robot tool (is it dangerous?), transported object (does it have sharp edges, can it fall on someone?), and work environment (temperature, chemicals) should be considered. All these factors must be assessed, and any risks minimized according to standards. Even when using a cobot, certain additional safeguards, such as laser radiation shields or operator helmets, may be necessary.

Cobot implementation errors and how to avoid them

To ensure successful cobot implementation, it's worth avoiding typical pitfalls:

-

Don't implement a cobot just because it's a "novelty."

-

How to avoid? Define a specific problem or need that the cobot should solve, and measurable goals (e.g., increase efficiency by X%, relieve workers at station Y, improve process Z quality). Make sure the goal is consistent with company strategy.

-

-

Skipping technical assessment can result in improper equipment selection or underestimating costs and integration time.

-

How to avoid? Conduct a feasibility study, analyzing the process step by step. Consult with cobot suppliers or integrators. Consider small-scale tests or showroom visits to verify assumptions in practice. Calculate ROI accurately, including purchase, integration, tooling, training, and downtime costs.

-

-

Shortening the testing and application tuning phase.

-

How to avoid? Plan a realistic schedule including off-line tests, pilot on actual workstation, and production startup with time buffer for troubleshooting. Involve operators in testing – their feedback can help catch problems.

-

-

While a cobot can work alone, it always requires supervision and operation.

-

How to avoid? Already at the planning stage, define the operator's role in the new station. Establish procedures for robot stoppage, who resets it and whether the operator has authorization. Make sure employees are aware of their role.

-

-

Neglecting safety is a serious mistake that can lead to accidents or problems with OHS inspections.

-

How to avoid? Treat the cobot like any other device subject to the Machinery Directive and conduct a full risk assessment, implementing appropriate measures. If in doubt, hire a machine safety specialist. Remember that crew training on robot collaboration principles is also a safety element.

-

-

Mismatching cobot to task (wrong model selection): Choosing a cheaper or available model that doesn't meet all application requirements can affect performance and durability.

-

How to avoid? Select model based on reliable data: required reach, payload (with reserve for gripper and forces during operation), and accuracy. Compare specifications of different brands and ask suppliers for 3D station simulations.

-

-

Lack of support or training from supplier: Insufficient use of available knowledge resources and support can hinder independent implementation.

-

How to avoid? Use official training and materials offered by manufacturers (e.g., UR, Fanuc, ABB, Doosan). Make sure the supplier offers local technical support. For first implementation, especially without experienced staff, consider working with an integrator to learn best practices.

-

Future of cobots and perspectives of their development

The cobot market is growing dynamically, and forecasts indicate that their role in industry will be increasingly important. In 2022, cobots already represented about 10% of all industrial robots installed worldwide, and their share continues to grow (International Federation of Robotics (IFR) data).

Main trends and development perspectives are:

-

Greater capabilities while maintaining safety: We can expect cobots with higher payloads and reaches, still meeting human collaboration standards. The boundary between "cobot" and "industrial robot" will blur, and classic robots will be equipped with sensors and safe collaboration modes.

-

Integration with artificial intelligence and machine vision: To expand the range of tasks, cobots will increasingly be equipped with advanced vision systems (2D/3D cameras) and AI algorithms. A camera on the robot wrist allowing object recognition and part orientation is becoming standard. In the future, thanks to AI, cobots will be able to learn new activities through demonstration (programming by demonstration with machine learning), where a worker manually shows the task and the robot generates the program itself. Development of computing power and cloud access (cloud robotics) will allow offloading cobots from expensive electronics, and difficult calculations will be performed in the cloud.

-

Unprecedented ease of use: Manufacturers aim to further simplify interfaces, introducing voice control, gestures, and even programming through augmented reality (AR). In the future, an operator using AR glasses could point out to the robot the points it should reach, and the system would automatically translate this into a motion program. Another trend is standardization of communication (e.g., OPC-UA Robotics) so that cobots of different brands integrate more easily with machines and factory systems (IoT).

-

New sectors and applications: Cobots will move beyond typical factories, finding applications in construction, agriculture (e.g., fruit picking), or healthcare (nurse assistants, rehabilitation robots). The boundary between collaborative industrial robot and service robot will blur. It's also possible that we'll see more mobile cobots in public spaces that will interact with people, e.g., providing information.

-

Better human-robot collaboration: The future of cobots is deeper cooperation, going beyond sequential coexistence. Thanks to improved control algorithms and sensors, the robot can become a true "colleague" in a task – e.g., jointly with a human screwing bolts to a large panel, reacting to the operator's current movements. Such responsive cooperation can significantly accelerate processes where previously two workers had to synchronize.

Summary

Cobots are a technology that is already changing the face of production, and in the coming years will become even more ubiquitous and useful. For your company, especially operating in metal processing, cobots can be a key element in increasing production volume, improving quality, reducing error and downtime costs, while improving working conditions and efficiently utilizing personnel for tasks where humans are irreplaceable (creativity, quality supervision).

Although cobotization is simpler than traditional robotization, it requires a conscious and methodical approach, including thorough analysis, planning, and reliable risk assessment. Starting with a pilot cobot project at one station, then gradually expanding automation to other areas, can help fully utilize the potential of this technology. In the era of Industry 4.0, digitization, and artificial intelligence, cobots perfectly fit the concept of smart factories, becoming one of the pillars of modern production.

Bibliography

- Aleksander Łukomski, Robotization of assembly processes, Design and Engineering Constructions, March/April 2023 https://konstrukcjeinzynierskie.pl/wp-content/uploads/PiKI_marzec_kwiecien_2023_darmowy.pdf

- Zbigniew Pilat, Wojciech Klimasara, Marek Pachuta, Marcin Słowikowski, Michał Smater, Jacek Zieliński, Possibilities of practical implementation of collaborative robots in various manufacturing technologies implemented in industrial environment, Measurements Automation Robotics 2018

- IFR WORLD ROBOTICS 2023 KEY TAKEAWAYS https://statzon.com/insights/ifr-world-robotics-2023#:~:text=IFR%20World%20Robotics%202023%20report,performance%20and%20fully%20digital%20production

- Mariusz Głowicki, Cobots - safety issues in collaborative robot integration, No. 4, April 2017